Emerald Bitumen is a division of Emerald Energy Ltd, an international energy company, the primary business of which you may find on its website under www.eeoil.com.

Emerald Bitumen is a division of Emerald Energy Ltd, an international energy company, the primary business of which you may find on its website under www.eeoil.com.

Emerald Bitumen Key Facts

- worldwide consumption is about 100 million tons every year

- 90% of all bitumen is used in road construction and only 10% for industrial purposes

- 95% of all roads are constructed using bituminous coatings

- 75% of black inks used for printing of daily newspapers as well as majority of black HP ink cartridges are made from Venezuelan bitumen

Petroleum Bitumen, normally called "Bitumen" or "Asphalt" is produced by refining crude oil. Used as a binder in road-building products, it is a very viscous, black or dark brown material.

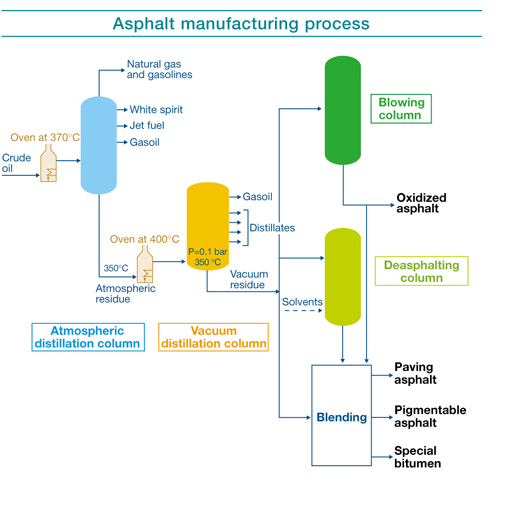

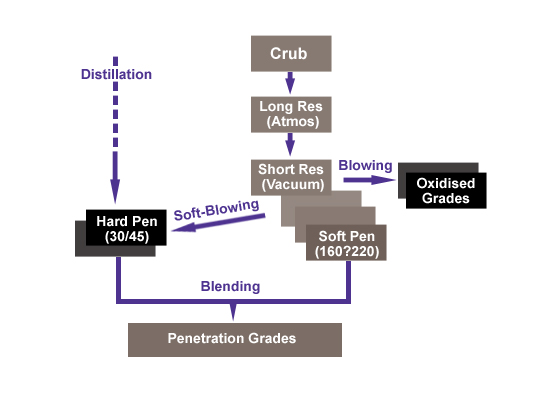

The crude oil is pumped from storage tanks, where it is kept at about 60°C, through a heat exchanger system where its temperature is increased to typically 200°C by exchanging heat gained from the cooling of newly produced products in the refining process. The crude is then further heated in a furnace to typically 300° C where it is partly vaporized into an Atmospheric Distillation Column. Here the physical separation of the components occurs. The lighter components rise to the top and the heaviest components (the atmospheric residue) fall to the bottom of the column and pass through a second heat exchanger prior to treatment in a vacuum distillation column. Finally, Bitumen, is obtained by vacuum distillation or vacuum flashing of atmospheric residue from the vacuum distillation column. This is "straight run bitumen". This process is called bitumen production by straight run vacuum distillation.

An alternative method of bitumen production is by precipitation from residual fractions by propane or butane- solvent deasphalting. The bitumen thus obtained has properties which derive from the type of crude oil processed and from the mode of operation in the vacuum unit or in the solvent deasphalting unit.

The grade of the bitumen depends on the amount of volatile material that remains in the product: the smaller the amount of volatiles, the harder the residual bitumen. In most cases, the refinery bitumen production by straight run vacuum distillation does not meet the market product quality requirements. Authorities and industrial users have formulated a variety of bitumen grades with stringent quality specifications, such as narrow ranges for penetration and softening point. These special grades are manufactured by blowing air through the hot liquid bitumen in a BITUMEN BLOWING UNIT and additional modification processes to the "straight run bitumen"

Specialists in bitumen view bitumen as an advanced and complex construction material, not as a mere by-product of the oil refining process.

TYPICAL BITUMEN PRODUCTION PROCESS

TYPICAL BITUMEN PRODUCTION SCHEME

CONTACT NOW for more enquiries